So at this point, I have a bunch of potentially dangerous sardine cans that I’ve extracted from a Nissan leaf “battery”.

Sometimes all this disassembly reminds me how everything in the world can be considered objects and classes of objects.

- Car

- Battery enclosure

- Battery group

- Battery module

- Parallel cell group

- Pouch cell

- Lithium plate stack

- Lithium substrate sheets

- LiMn2O4 with LiNiO2 Cathode (+)

- Graphite (C) Anode (-)

- Lithium substrate sheets

- Lithium plate stack

- Pouch cell

- Parallel cell group

- Battery module

- Battery group

- Battery enclosure

This reminds me of something…

You will notice at the bottom of the groups is a class – the cathode and anode. That is the single thing – the coin with two faces – that makes up every lithium battery. The chemistry changes, but basically any classic battery you’ve ever seen is assembled this way. Once you’ve got that idea down, the rest is just optimizing electron flow through all your “two sides of the same coin”.

The battery arrangement I will be using is a series and parallel arrangement, since I want both an increase in voltage and ampacity.

Taking inventory

I took all the batteries out of their little groups that came from the leaf enclosure, and lined them up on my makeshift table. This is a little over 400 lbs of modules.

I had to purchase an additional single module from ebay, because I wanted to build a 48 volt nominal pack, which means a voltage range between 58.8 absolute maximum volts, and 42 absolute minimum volts. Divide that voltage by 7, and we get a range of 6.00 to 8.4 volts per module. Then, divide those in half to get the individual pouch voltage of 3 to 4.2 volts.

The actual chemistry itself defines the min and max voltage characteristics. This means you can theoretically store power until 4.2 volts, and deplete (use) power until 3.0 volts. However, that sort of action would damage the chemistry quickly. Instead, we will perhaps de-rate our maximums to 3.3 volts discharge, and 4.05 volts charged, per cell.

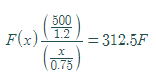

The formula used to factor the capacity is based on the max watt-hours of the module and it’s voltage range, and the proposed reduced voltage range for extended life.

| Safe chemistry bounds | vMax | vMin | vRange | Potential Capacity | Max Capacity @ 49 modules |

| Reduced lifetime | 4.2 | 3.0 | 1.2 | 500 Ah | 24.50 kWh |

| Extended lifetime | 4.09 | 3.19 | 0.94 | 391.6 Ah | 19.18 kWh |

| Mega Extended lifetime | 4.05 | 3.3 | 0.75 | 312.5 Ah | 15.31 kWh |

Whats inside

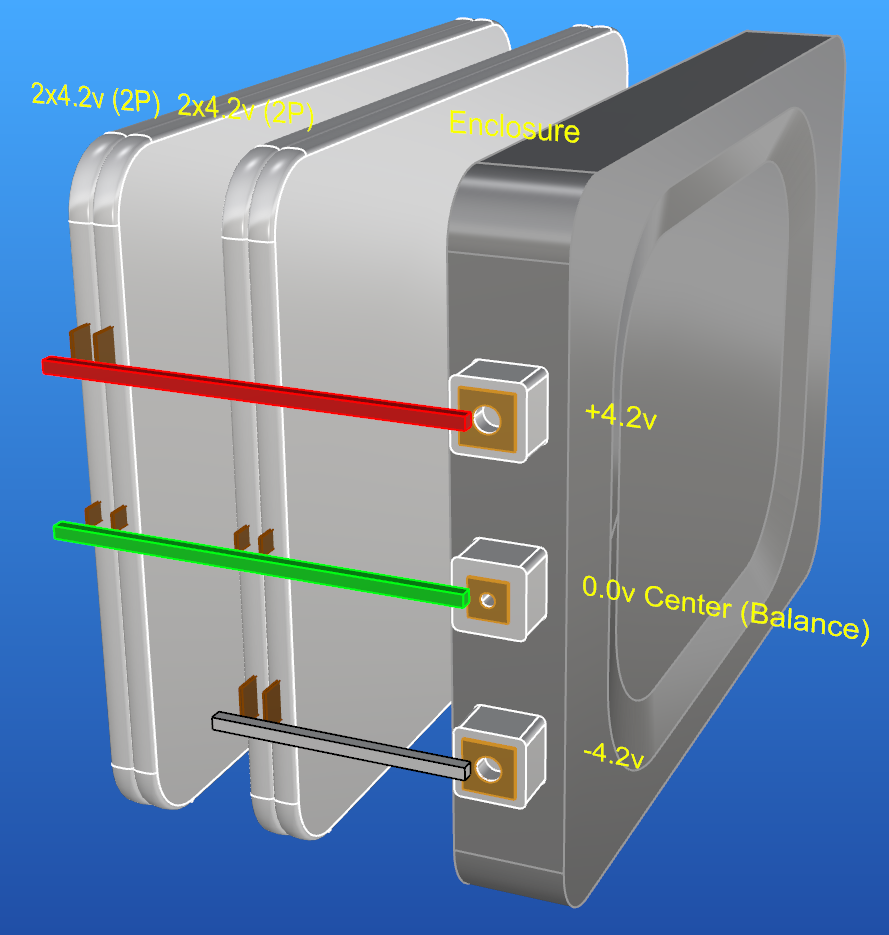

In a little more detail, there are 4 foil lithium battery pouches, wired in series and parallel – the way to call this is 2P2S configuration.

Check out the drawing; you can see I’ve noted a +4.2v and a -4.2v side of the battery – I don’t mention 8.4v anywhere. That’s because it’s simply two groups (the 2P part) connected in series (the 2S part).

The center reference balance is the terminal between the two batteries. This is no different than a flashlight stacking up D batteries in the handle. If you only measured between the individual D batteries in the flashlight, you’d only get 1.5 volts between them.

In this manner, it’s possible to “see into” each battery module more effectively, and help balance any differences between the packs that appear over time. If you measure from the center tap to either of the big terminals, you’ll get either a positive or negative voltage indicated on your measuring equipment.

That extra battery

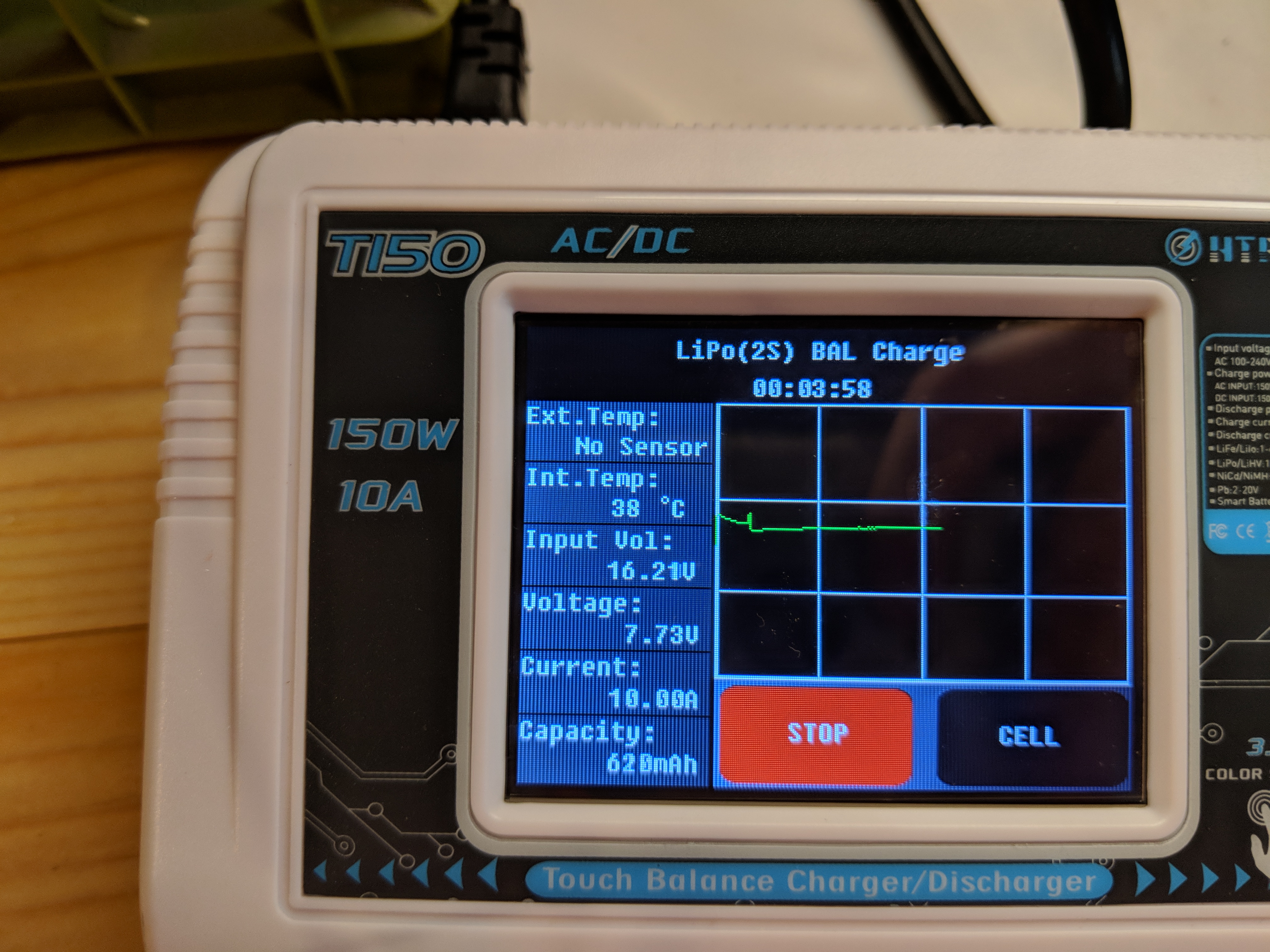

So like I mentioned, an extra battery was acquired to build the correct battery pack topology. Since that extra battery came from a different system, it probably has experienced a slightly different life. You can see that it’s only a “little” different in voltage (7.82 vs 7.96), but when you consider the capacity of the module, it’s quite a bit of watts in difference.

Any batteries you introduce to the system should be all similar to each other. Later, when it’s all wired up, a BMS – Battery Management System can be used to actively balance the batteries as their slight physical differences are found.

It’s cousins were a little bit different voltage, and they were all exactly the same, to about 1/100th of a volt. The Nissan BMS is effective.

I used a small form factor lithium battery charger off amazon that has a very useful feature, the ability to set a max charge voltage per cell.

The charger is capable of balance charging – meaning, shunting extra power to and from the other cells in a parallel group, up to 6 members.

I set the charger to stop at 3.98 volts per cell, although it overshot by just a few millivolts. I’ll use a cheap car headlamp to draw the battery back down to 7.96 volts again. I’ll excuse the charger, it really had no idea there was a 55,000 mAh battery attached to it, so who knows what it’s little capacity algorithm was thinking.

Whats next

Now that some battery basics (specific to the Leaf modules, I suppose) are discussed, it’s now time to get to physically putting them together in a way that is secure. Some of the requirements are obvious, like 48 volts, but some are a little hard to think about – like how to reduce the likelihood of rapid automatic disassembly (an explosion)

I’ll talk about that in another post.